A Mechanical Engineer with interest in Automotive Technology; Srinivas Devathi goes on to invent Cool Car Technology with which you can change the Color of your car from any color to any other color in under 10 minutes, repeatably. USA (USPTO) issues patent on invention with patent # US 8,910,998 B1 (The grant is valued at 22.5 Trillion Earthlings / $). The buttons to ‘View the Patent Grant’ and ‘Download the Patent Grant’ are given below. In the rest of the page there are ‘Early stage trials of the technology’ video files; which will give you a visual understanding of the Technology and concept. There are also couple Audio files towards the end of this page, which will give the ‘Financial benefits to Automotive Industry’ and ‘Mechanical Engineering technical aspects’ of the cool Technology.

Cool Technology Early Trials by DSS

Early stage trials by Srinivas with plastic covers and toy car models. This was the first time Srinivas demonstrated the technology on a toy car. It gives a good visual understanding of the concept. It looks absolutely elementary. NO polymers, chemicals, additives delivering required properties to the vest yet. No robotic color change process, automation outlined yet. The complete technology is yet to evolve and is currently in varying stages of evolution and trials.

Next Stage Trials of Cool Technology by DSS

We tried multiple polymer, plastic sheets with varying textures to create many variants of 2-layer vests. Attached them to the bonnet of car. This stage allowed us to explore multiple fastening techniques for attaching the vests to the vehicle panel. We have had incremental improvements and learning in each trial. However, the technology is far from fully evolved at our end. The vest outer layer has to be of thicker guage to avoid deformation and needs more additives, chemicals to deliver additional properties. Robotic incisions and automation is still under works. More trials with better composites, polymers are ongoing. The right robotics team is being set-up. Stay tuned for more demonstration videos which will be put out soon.

To:

Automotive Industry CEO’s, CTO’s and CFO’s.

Audio recording of the ‘Automotive OEM benefits from Cool Technology adoption’ by Inventor Srinivas Devathi is given below. Cool Technology makes a compelling case for CEO’s, CTO’s and CFO’s of automotive industry, to adopt and transition into. The OEM financial benefits recording audio file (Play bar given below) gives valuable insights and data pertaining to costs, benefits and financial merits such as profitability when an OEM adopts and transitions to Cool Technology. This audio is for the OEM executive teams; in particular to the CEO, CFO and CTO.

To:

Automotive Industry R&D division and Technology teams.

Audio recording of the ‘Mechanical Engineering aspects of Cool Technology’ by Inventor Srinivas Devathi is given below. This Cool Technology recording audio file (Play bar given below) gives valuable insights into mechanical engineering and design details pertaining to cool technology. Everyone in the technology and R&D divisions will relate to the content in this audio file. Especially, Material science scientists, Control engineering and Robotics scientists will like the content in the audio.

Invention, early designs and drafting / filing of priority application:

Invention: In Q1-Quarter one-2007 I came up with the ‘Vehicle Color Change Technology’ invention after buying my third used silver car (Nissan Altima) as I could not find a used car in the color of my choice within my budget. As I pondered on the problem of getting it re-painted, I came up with the solution of defining a thin fluid tight space between two layers on the vehicle surface, to reuse the space for repeatable color change.

Early designs in Q1-Quarter One-2007 and solving the design limitations: My first design was a shell or panel on top of the existing vehicle panel, to define the fluid tight space. However, given my mechanical engineering background, I was quick to realize that this design was not ‘production viable’ and I may have challenges in ‘Industrial applicability’ area of the invention. The shell outer layer has its share of problems – fabrication, hardness, brittleness and could easily fracture upon accident or other minor incidents. Most important problem was the challenge in production or fabrication; in such a design. I do discuss this design as one of the five designs in my patent text (explained as drawing figure 4).

Solving this was relatively easy; given the ‘Material science’ subject and its importance in Mechanical and automotive engineering. Material Science is a vast (ocean like) subject with scientists trying many combinations of bringing materials together and further in varying proportions and in many varying techniques of blending them together. So, building a polymer or composite which will deliver all the required properties to the two-layer system was the next logical and obvious solution; which will eliminate all the limitations in a shell / panel design as listen in paragraph above. It is material science that has delivered a vast list of weird substances in the world already. And certainly, when Material Science practitioners try this technology; various combinations of polymer resins will evolve; and the technology will optimize over years to come.

The drafting of the patent in Feb and March of 2014:

As the solution of the design problem was complete and resolved in Q1-2007 itself, drafting the patent text in Feb-March of 2014, discussing and detailing the designs was now time & effort. I discuss five designs in my patent text as shown in drawing figures 2, 3, 4, 5 and 6. In the patent text I also strive to list a super-set of all materials that could deliver the required (basic) properties to the two-layer polymer system. As you see by the list of materials, they deliver properties such as rubberiness, stretchability, flexibility and elasticity.

Materials listed in the specification for building the polymer system – polyester, acrylic, fiberglass, polyethylene, plastic, silicone, polypropylene, polystyrene, polyester, glass, fiber, thermoplastic, thermoset, latex, polymer fibers, polyvinyl chloride, polyethylene terephthalate, nylon, vinyl, thermoplastic materials, thermoset materials, phenolics, furane resins, amino resins, epoxy, alkyds, allyl plastics, aminos, polyamides, polyethylene resins, polycarbonate, acrylic resin, cellulose acetate, cellulose nitrate, cellulose acetate butyrate, cellulose propionate, rubber, neoprene, Thiokol, nitrile, butyl rubber, silicone rubber, acetals, cellulosics, fluoroplastics, ionomers, polyimide, polyolefins, polysulfone, composites, polythene, epoxides, polyurethane, synthetic rubber, synthetic plastic, synthetic resin, or combinations thereof.

Elaboration opportunities that were missed while drafting the patent:

Properties paragraph: While I listed all the polymers / materials that could be used for building the two-layer polymer system, I missed out on the opportunity to elaborate and describe the properties of the two-layer system in an exclusive paragraph. The properties which the two-layer system must have are at least partial rubberiness or at least partial stretchability or at least partial elasticity. Of course, I do discuss hydrophobic coating, transparency and other properties in great lengths of detail in the patent text.

Fits and Joins paragraph: Another paragraph which I would have liked to include in the patent text is the discussion (or description) on various types of fits / joins to attach the two-layer polymer system to the vehicle surface. There are various fits available in mechanical engineering practices. Fittings / joins is a subject dealt in detail in Mechanical Engineering and Automotive Engineering. Automotive and air-craft OEM’s bring together 3,000 to 10,000 components or parts together; all of which are joined / fitted together. So, fittings / joins; is a broad subject in Mechanical Engineering. Some of the commonly used fits are Shrink fit, regular fit, tight fit, snug fit; to name a few. I would have liked to elaborate and discuss fittings in one paragraph and describe the join / fit between two-layer polymer system and vehicle surface as a ‘Snug fit’. That is an appropriate fit for this join. Another way of explaining this fit for a ‘common man’s understanding’ is a ‘hand in a glove’ kind of a fit; maybe a surgical glove as compared to other gloves, which could be a loose or regular fit.

Discussion of five designs described: Another paragraph which I would have liked to include in my patent text was a comparison of five designs that I propose (seen in drawing figures 2, 3, 4, 5 and 6) and discuss the merits, demerits, pros & cons of all five designs; and recommend the most popular and widely applicable design (most likely to be practiced in future). The most popular design that would be adopted by all future technology practitioners is the design as described in drawing figure 3. A two-layer polymer system installed on the exterior side of the vehicle surface. From a multitude of vantage points, design explained in drawing figure 3 will be the most widely adopted in the world. Further design described in drawing figure 6 (behind a transparent vehicle potion) may have wider adoptability than the other three designs described in drawing figures 2, 5 and 4). Designs described in drawing figures 2 and 5 have color / fluid interaction related problems with the surface (corrosion or other long-term effects / damage). Design described in drawing figure 4 has production / fabrication challenges and hence Industrial applicability.

Terminology:

Technical people terminology: Mechanical engineering technology practitioners / technical R&D teams / OEM technicians; can use and understand the terminology of two-layer system or two-layer polymer system or two-layer resin system or two-layer composite system to be installed on exterior vehicle panels. The technology people very easily and clearly understand these terms and usage.

My style of writing and common man terminology: My style of writing / drafting is such that, while I describe complex technical details or a complex solution to a problem; I have always strived to write in a way that even a ‘common man’ can easily understand. So, I was trying to find a simple commonly used word for the two-layer system to be attached to the vehicle panel, which also explains the required properties that the two-layer system must have. The properties include at a minimum; rubberiness, stretchability and some degree of elasticity in the system. So, I decided on the usage of word ‘vest’. And you see that I have used it in my patent text. This was done for ease of understanding of the two-layer system to be installed on the vehicle along with the understanding of the required properties for the two-layer system for a ‘common man’. I felt the word vest would give such an understanding as opposed to the other words like glove or jacket (considered at the time). Hence, I used the word vest (for common man’s easy understanding of the two-layer polymer system) in the patent text. I have worn vests of the brand ‘VIP’ most of my life (while in India) and they have nothing to do with my invention.

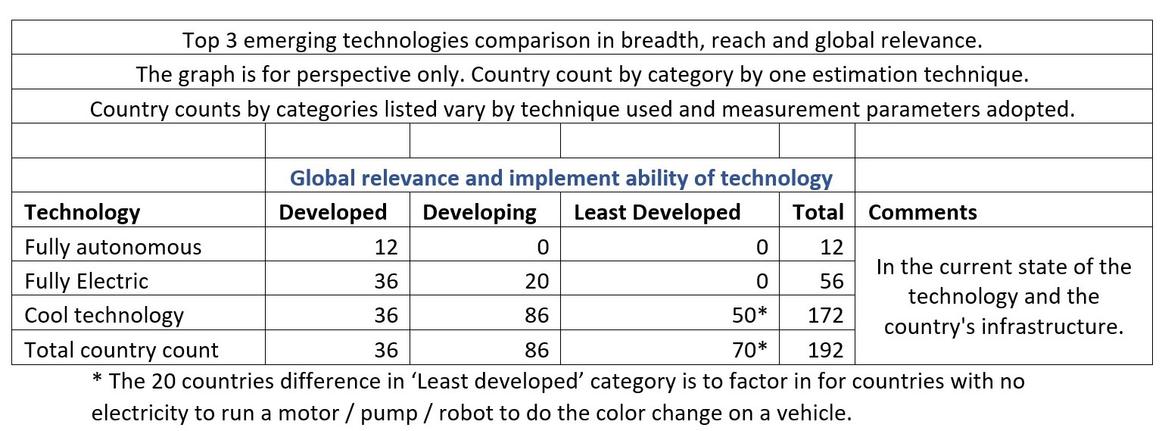

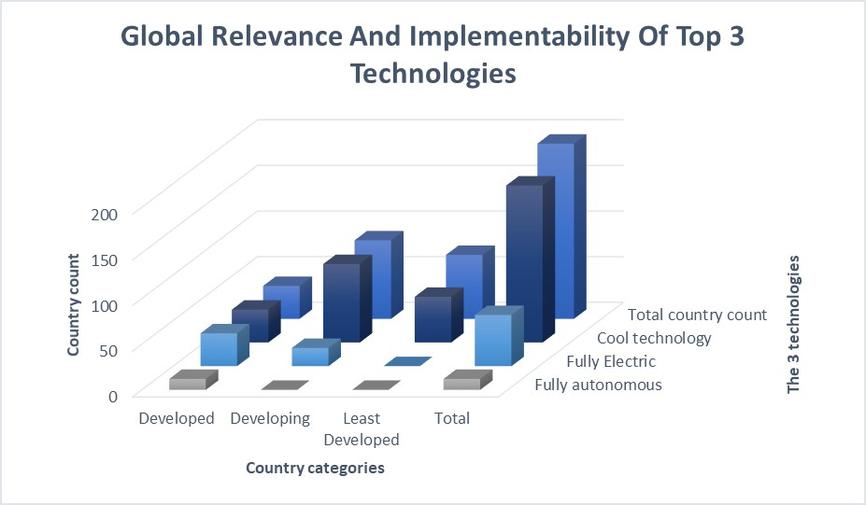

Global Relevance of Cool Car Technology

R&D budget allocations for Vehicle color change technology or Cool technology.

And global relevance of top 3 emerging automotive technologies.

Automotive industry has not been in such a transformative phase ever before, given the emerging technologies. Most OEM’s are focused on launching fully autonomous vehicles or introducing hybrid vehicles or fully electric vehicles. However, these technologies may not all be globally relevant. E.g., Fully autonomous vehicles are being tried and tested in developed countries which have the necessary infrastructure and driving discipline in place. The same technology is not a straight-forward roll out in developing countries or least-developed countries. The necessary infrastructure is not in place. The same analogy could be extended for rolling out electric vehicle technology.

Srinivas Devathi is introducing a technology with which the consumer could change the vehicle color from any shade/color to any other shade/color, repeatedly. This is a technology which is most globally relevant, as it can be sold in all the countries in the world. This is going to be one of the largest transformation the industry has seen since its inception. This will also be one of the most visually tantalizing transformation mankind has seen. This technology / concept sells itself; given the multitude of benefits that it delivers to all the stakeholders in automotive industry. The biggest of benefits reaped by the OEM’s themselves.

OEM benefits:

- OEM could potentially decommission the ‘Paint shop’ in their automobile plant within a few years. With a robust transition plan, the decommissioning of ‘Paint shop’ is not just possible at one plant, but all the manufacturing plants. Significant ‘capital investment and cost reduction’ would be realized.

- The quarterly / annual ‘Operational costs’ related to conventional painting could be fully eliminated. Reduced capital investment and reduced operational costs, would mean reduced ‘Financing costs’.

- Hazardous environment (in the form of paint shop) is eliminated for OEM manufacturing plant employees.

- OEM’s could manufacture, maintain inventory and transport vehicles only by model / variant and not by color.

- OEM’s would realize inventory management cost and transportation cost savings.

- Most importantly, they can now deliver the car to consumer in the shade / color of consumers choice without any delays or special orders.

- Per unit paint costs are reduced by at least 5%.

- Overall painting costs are reduced by 5-10%.

- A ‘Cool car’ could easily be priced 5-10% higher for the ‘Repeatable color change feature’ delivered to consumers. This could be a new variant in existing vehicle models or a brand-new model by itself.

- Finally, the most important of them all, OEM’s will realize increased sales and profits.

- The auto parts / spares business would have additional stream of income in the form of Vest manufacturing / replacement sales. Not just for current year vehicle models, but also for all the OEM past vehicle / car models. These vests would be directly sold to ‘Regular car to Cool car’ conversion businesses, via an e-sales channel.

- The benefits listed above for OEM’s shall continue for many decades to come.

Consumer benefits:

- Can get a car in the shade of their choice, out of 1800 plus shade / color options.

- No wait time, to get the car of their choice in the shade / color of their choice.

- Need not stay with the same color. Can change the color of the car for an affordable price repeatedly as and when they want.

- Can also opt for their current car (conventionally painted car) to be converted to a ‘Cool car’ for a reasonable price, as compared to replacing the car.

Dealer benefits:

- Reduced inventory management costs, as inventory management is by car model / variant and not by color.

- Lower dealership set-up costs, due to lesser parking space requirement.

- Increased profitability.

- Can deliver the car immediately in the color / shade choice of consumer.

There are other supplier side benefits and plenty of ‘New business opportunities’ for MSME segment. This results in business growth, job growth and positive impact on economics.

Given all the benefits listed above, the technology sells itself. Further, this technology will have global demand; irrespective of developed, developing or least-developed country statuses. It is impossible for OEM’s, dealers, suppliers, public to ignore this technology / concept any more. Hence OEM’s are considering allocating 5-10% of their R&D budgets to implement this technology and roll-out the first ‘Cool car’ of their brand within the next year or two. If your company has not already allocated the R&D budget for launching this vehicle color change technology, the Inventor requests that this technology be listed in your annual budget discussions as applicable for the next 1 to 3 years, to ensure that you do not fall behind in launching the ‘Cool model’ of your brand. Given the likelihood of the technology catching on; with in a decade, your company may not be manufacturing the conventionally painted vehicles. This concept and technology cannot be ignored any more. Based on conversations with different people within industry and outside, as Inventor I know that the time for this technology has come.

Feel free to write, discuss, open a dialog, give feedback, share your thoughts on the technology roll-out with Srinivas Devathi by sending an e-mail to Srinivas@Coolcartechnology.com. You can also write on the website www.CoolCarTechnology.com, by clicking the contact tab. The table and graph attached with this news-letter, is only to give a perspective on the global relevance and implement ability of top 3 automotive technologies. The total country counts have been derived from UN data based on one method of categorization. Note that there are other counts based on measurement techniques / parameters used.

Article written by:

Srinivas S. Devathi,

Inventor of Cool Technology